products

Outdoor Cable

Your current location: Home > Products > Outdoor Cable

Description:

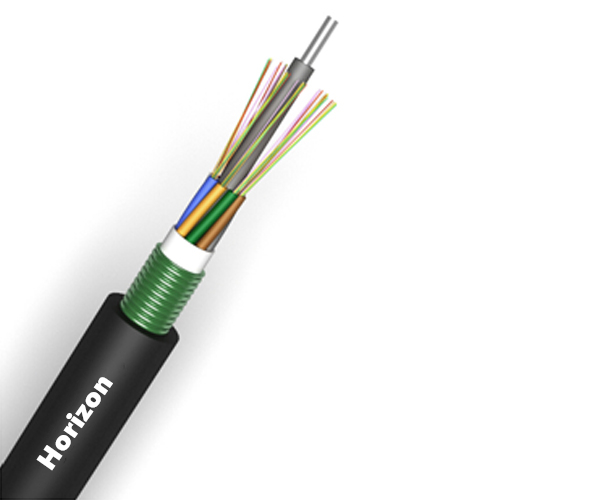

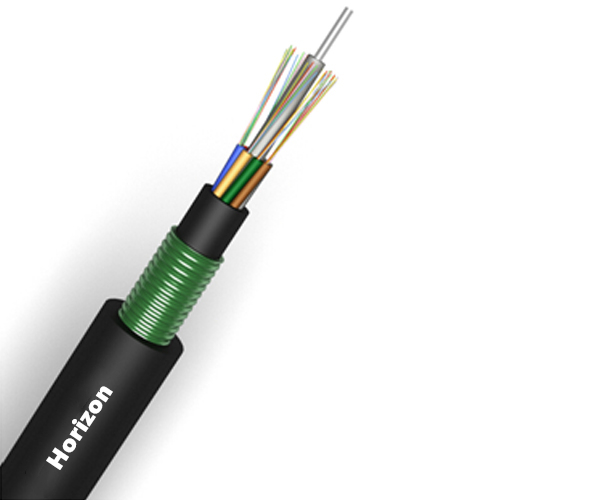

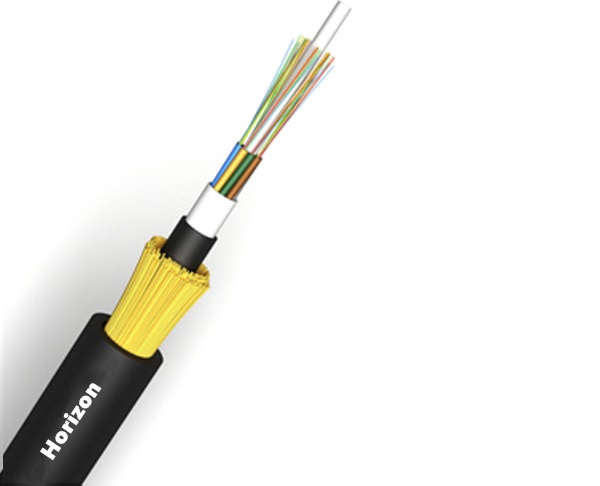

The loose tubes are made of high modulus plastics (PBT) and filled with water resistant filling gel. Loose tubes are stranded around the metallic central strength member, cable core is filled with cable filling compound. The corrugated aluminum tape is longitudinally applied over the cable core, and combined with polyethylene (PE) inner sheath. Galvanized steel wires are stranded around inner sheath, and then extruded with PE outer sheath.

Application:

Underwater installation (lake, river etc.)

Direct-buried installation

Duct installation

Backbone network and metro network

Features:

Excellent transmission, mechanical and environmental performance

Superior crush resistance and tensile strength performance

Applicable to harsh environment

Environmental Conditions:

Storage/Operating Temperature : -40℃ to + 70℃

Installation Temperature : -30℃ to + 60℃

Packing and Lengths:

Packing: Wooden drums

Lengths (tolerance ±1%): 2-4km

Customised drum lengths available on request.

Standard:

IEC-60793-1, IEC 60793-2, IEC-60794-1, TIA/EIA-598-A, Telcordia GR-20-CORE,

ITU-T Recommendation G.652D/G.655/G.657A1/G.657A2/G.657B3, ISO/IEC 11801

| Fiber Count | Cable Diameter (mm) | Cable Weight (kg/km) | Tension Strength (N) (Long/Short Term) | Crush Load (N/100mm) (Long/Short Term) | Bending Radius (Static/Dynamic) |

| 6 | 14.6 | 462 | 20000/40000 | 4000/6000 | 10D/20D |

| 12 | 14.6 | 462 | 20000/40000 | 4000/6000 | 10D/20D |

| 24 | 14.6 | 462 | 20000/40000 | 4000/6000 | 10D/20D |

| 36 | 15.0 | 486 | 20000/40000 | 4000/6000 | 10D/20D |

| 48 | 15.7 | 533 | 20000/40000 | 4000/6000 | 10D/20D |

| 60 | 15.7 | 533 | 20000/40000 | 4000/6000 | 10D/20D |

| 72 | 16.0 | 553 | 20000/40000 | 4000/6000 | 10D/20D |

| 96 | 17.6 | 633 | 20000/40000 | 4000/6000 | 10D/20D |

| 120 | 19.2 | 766 | 20000/40000 | 4000/6000 | 10D/20D |

| 144 | 21.3 | 996 | 20000/40000 | 4000/6000 | 10D/20D |

Optical Parameters:

| Fiber Type | G.652D | G.655 | G.657A1 | G.657A2 | G.657B3 | OM1 | OM2 | OM3-150 | OM3-300 | OM4 |

| Core/Cladding Diameter (μm) | 9/125 | 9/125 | 9/125 | 9/125 | 9/125 | 62.5/125 | 50/125 | 50/125 | 50/125 | 50/125 |

| Attenuation @850nm (dB/km) | - | - | - | - | - | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 |

| Attenuation @1300nm (dB/km) | - | - | - | - | - | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 |

| Attenuation @1310nm (dB/km) | 0.36 | 0.36 | 0.36 | 0.36 | 0.36 | - | - | - | - | - |

| Attenuation @1550nm (dB/km) | 0.22 | 0.22 | 0.22 | 0.22 | 0.22 | - | - | - | - | - |

| OFL Bandwidth @850nm (MHZ·KM) | - | - | - | - | - | ≥200 | ≥500 | ≥700 | ≥1000 | ≥3500 |

| OFL Bandwidth @1300nm (MHZ·KM) | - | - | - | - | - | ≥500 | ≥500 | ≥500 | ≥500 | ≥500 |

| Effective Modal Bandwidth @850nm (MHZ·KM) | - | - | - | - | - | - | - | ≥950 | ≥2000 | ≥4700 |

| Support Distance on Gigabit Ethernet LX 1300nm (m) | - | - | - | - | - | 550 | 550 | 550 | 550 | 550 |

| Support Distance on Gigabit Ethernet SX 850nm (m) | - | - | - | - | - | 275 | 550 | 750 | 800 | 880 |

| Support Distance on 10 Gigabit Ethernet SX 850nm (m) | - | - | - | - | - | 33 | 82 | 150 | 300 | 550 |

| Support Distance on 40G/100G Ethernet SX 850nm (m) | - | - | - | - | - | - | - | - | 100 | 150 |

| Min. Bending Radius (mm) | 30 | 30 | 10 | 7.5 | 5 | 30 | 30 | 30 | 30 | 30 |

| Fiber No.: | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| Fiber Color: | Blue | Orange | Green | Brown | Gray | White | Red | Black | Yellow | Violet | Pink | Aqua |

| Loose Tube No.: | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| Loose Tube Color: | Blue | Orange | Green | Brown | Gray | White | Red | Black | Yellow | Violet | Pink | Aqua |